Toyota 4Runner: Short to GND in Motor LH Circuit (21,23)

DESCRIPTION

When there is a short to GND in the side auto step motor circuit, the side auto step controller ECU assembly does not operate the automatic running board.

|

DTC No. |

Detection Condition |

Trouble Area |

|---|---|---|

|

21 |

Short to GND in the circuit on the stowing or deploying side of the side auto step motor LH. |

|

|

23 |

Short to GND in the circuit on the stowing or deploying side of the side auto step motor RH. |

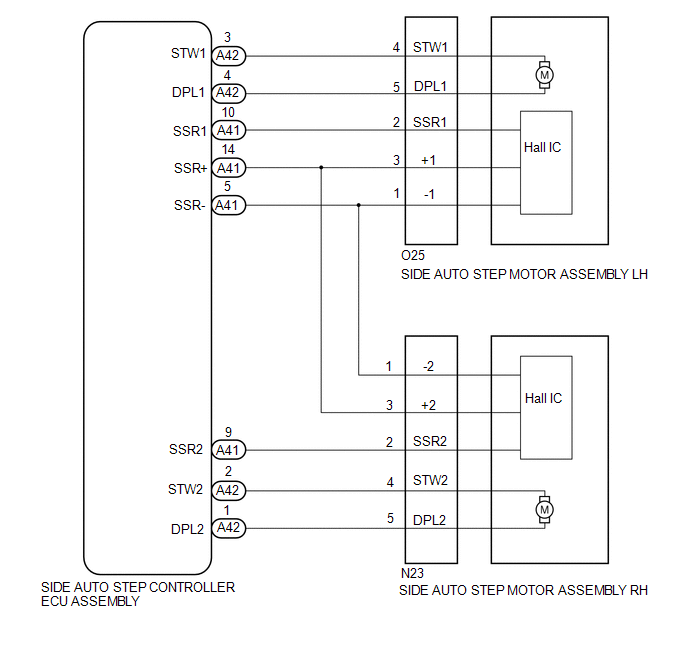

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT SIDE AUTO STEP MOTOR ASSEMBLY |

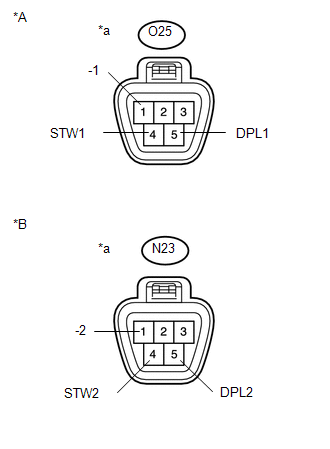

(a) Disconnect the O25*1 or N23*2 side auto step motor assembly connector.

- *1: for LH

- *2: for RH

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance: for LH

for RH

|

|

| NG | .gif) |

REPLACE SIDE AUTO STEP MOTOR ASSEMBLY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (SIDE AUTO STEP MOTOR - SIDE AUTO STEP CONTROLLER ECU) |

(a) Disconnect the A42 side auto step controller ECU assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-3 (STW1) - Body ground |

Always |

10 kΩ or higher |

|

A42-4 (DPL1) - Body ground |

Always |

10 kΩ or higher |

for RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-2 (STW2) - Body ground |

Always |

10 kΩ or higher |

|

A42-1 (DPL1) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE SIDE AUTO STEP CONTROLLER ECU ASSEMBLY |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Short in Motor LH (11,12)

Short in Motor LH (11,12)

DESCRIPTION

When there is a short in the side auto step motor circuit, the side auto step

controller ECU assembly halts the operation of the automatic running board.

DTC No.

...

Side Auto Step ECU Power Source Circuit

Side Auto Step ECU Power Source Circuit

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following

inspection procedure.

PROCEDURE

1.

...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 2 TELEPHONE BRACKET

(a) Install the bracket with the 2 bolts.

2. INSTALL NO. 1 TELEPHONE BRACKET

(a) Install the bracket with the 3 bolts.

(b) Connect the 2 connectors.

3. INSTALL MAYDAY BATTERY WITH BRACKET

(a) At ...

Accessory Meter

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

battery terminal to disable the SRS system.

N ...

0.0184

.gif)