Toyota 4Runner: Speed Signal Malfunction (B15C2)

DESCRIPTION

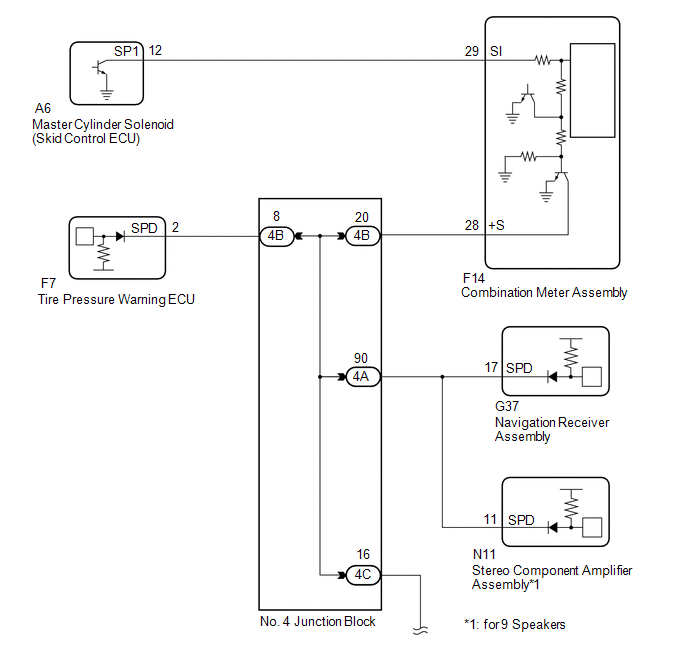

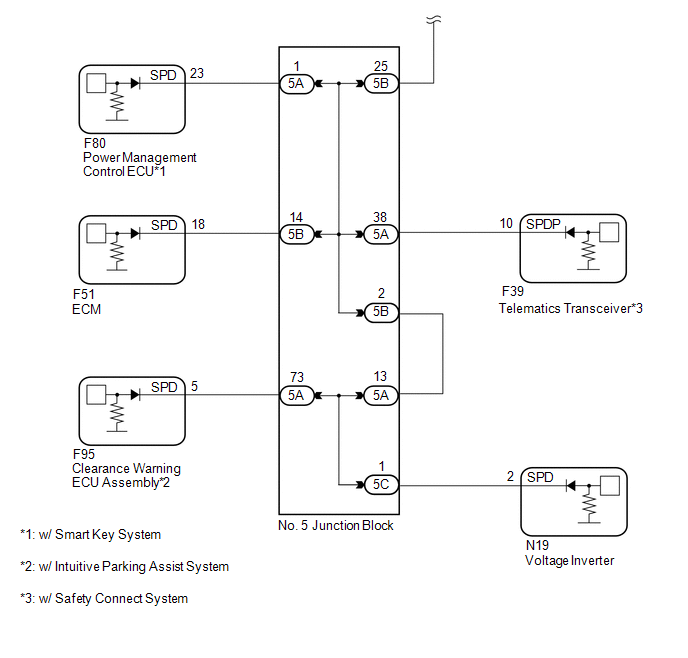

The navigation receiver assembly receives a vehicle speed signal from the combination meter assembly and information from the navigation antenna assembly, and then adjusts the vehicle position.

The navigation receiver assembly stores this DTC when the difference between the speed information that the navigation antenna assembly receives and the SPD pulse received from the combination meter assembly becomes large.

HINT:

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter assembly. The signal is changed to a pulse signal at the transistor in the combination meter assembly. Each ECU controls the respective systems based on the pulse signal.

- If a short occurs in any of the ECUs or in the wire harness connected to an ECU, all systems in the diagram below will not operate normally.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B15C2 |

A difference between the GPS speed and SPD pulse is detected. |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

After replacing the navigation receiver assembly of vehicles subscribed to pay-type satellite radio broadcasts, registration of the XM radio ID is necessary.

PROCEDURE

|

1. |

CHECK VEHICLE SENSOR (OPERATION CHECK) |

|

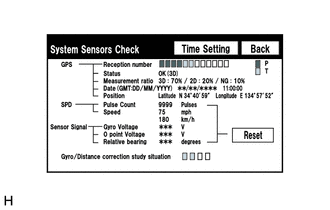

(a) Enter the "System Sensors Check" screen. Refer to Check GPS and Vehicle

Sensors in Operation Check (See page |

|

(b) While driving the vehicle, compare the value of "Speed" to the reading on the speedometer. Check if these readings are almost equal.

OK:

The readings are equal or almost equal.

| OK | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

|

|

2. |

INSPECT COMBINATION METER ASSEMBLY (OUTPUT WAVEFORM) |

|

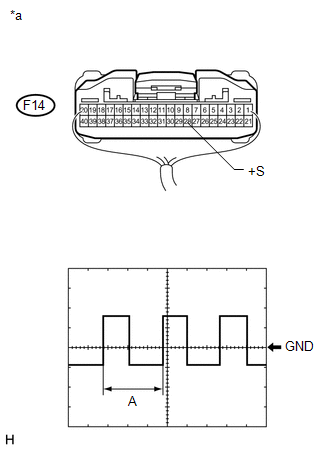

(a) Check the output waveform. (1) Remove the combination meter assembly with the connector(s) still connected. (2) Connect an oscilloscope to terminal F14-28 (+S) and body ground. (3) Turn the ignition switch to ON. (4) Turn a wheel slowly. (5) Check the signal waveform according to the condition(s) in the table below.

OK: The waveform is similar to that shown in the illustration. HINT: When the system is functioning normally, one wheel revolution generates 4 pulses. As the vehicle speed increases, the width indicated by (A) in the illustration narrows. Text in Illustration

|

|

| NG | .gif) |

GO TO METER / GAUGE SYSTEM |

|

|

3. |

INSPECT NAVIGATION RECEIVER ASSEMBLY (OUTPUT WAVEFORM) |

|

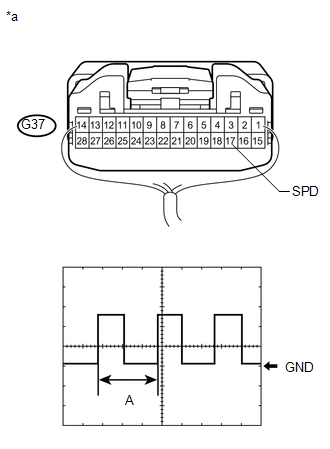

(a) Check the output waveform. (1) Remove the navigation receiver assembly with the connector(s) still connected. (2) Connect an oscilloscope to terminal G37-17 (SPD) and body ground. (3) Turn the ignition switch to ON. (4) Turn a wheel slowly. (5) Check the signal waveform according to the condition(s) in the table below.

OK: The waveform is similar to that shown in the illustration. HINT: When the system is functioning normally, one wheel revolution generates 4 pulses. As the vehicle speed increases, the width indicated by (A) in the illustration narrows. Text in Illustration

|

|

| OK | .gif) |

REPLACE NAVIGATION RECEIVER ASSEMBLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - NO. 4 JUNCTION BLOCK) |

(a) Disconnect the F14 combination meter assembly connector.

(b) Disconnect the 4B No. 4 junction block connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

F14-28 (+S) - 4B-20 |

Always |

Below 1 Ω |

| NG | .gif) |

REPAIR OR REPLACE HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - NO. 4 JUNCTION BLOCK) |

|

|

5. |

CHECK HARNESS AND CONNECTOR (NAVIGATION RECEIVER ASSEMBLY - NO. 4 JUNCTION BLOCK) |

(a) Disconnect the G37 navigation receiver assembly connector.

(b) Disconnect the 4A No. 4 junction block connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G37-17 (SPD) - 4A-90 |

Always |

Below 1 Ω |

| OK | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (NO. 4 JUNCTION BLOCK) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (NAVIGATION RECEIVER ASSEMBLY - NO. 4 JUNCTION BLOCK) |

GPS Antenna Connection Malfunction(short) (B15C0,B15C1)

GPS Antenna Connection Malfunction(short) (B15C0,B15C1)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the navigation antenna assembly.

DTC No.

DTC Detection Condition

Trouble Area

B15C0

...

Speaker Output Short (B15C3)

Speaker Output Short (B15C3)

DESCRIPTION

This DTC is stored when a malfunction occurs in the speakers.

DTC No.

DTC Detection Condition

Trouble Area

B15C3

A short is d ...

Other materials about Toyota 4Runner:

Manual Shifting Test

MANUAL SHIFTING TEST

1. MANUAL SHIFTING TEST

HINT:

Through this test, it can be determined whether the trouble occurs in

an electrical circuit or if it is a mechanical problem in the transmission.

If any abnormalities are found in the fol ...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

0.0071

.gif) ).

).

.gif)