Toyota 4Runner: Disassembly

DISASSEMBLY

PROCEDURE

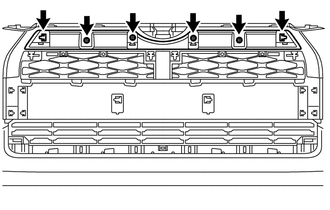

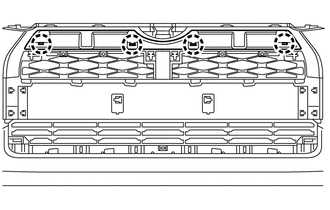

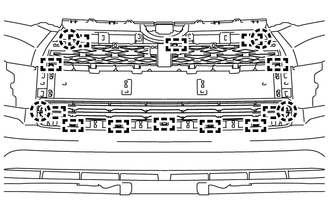

1. REMOVE RADIATOR GRILLE

.gif)

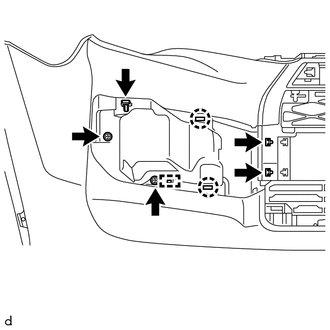

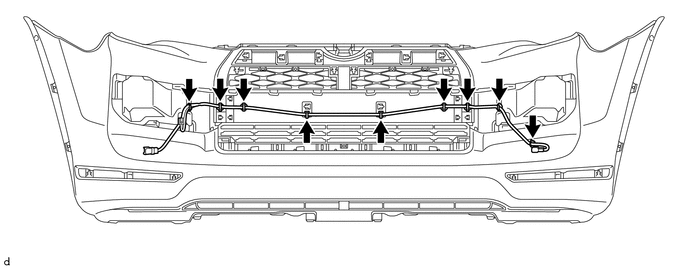

2. REMOVE NO. 2 ENGINE ROOM WIRE

(a) Disconnect each connector.

(b) Detach the 9 clamps to remove the No. 2 engine room wire.

3. REMOVE NO. 1 ULTRASONIC SENSOR

.gif)

4. REMOVE ULTRASONIC SENSOR CLIP

.gif)

5. REMOVE NO. 2 ULTRASONIC SENSOR RETAINER

.gif)

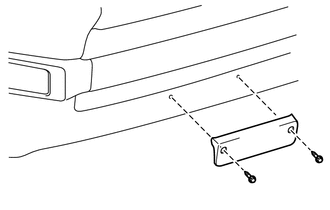

6. REMOVE FRONT BUMPER EXTENSION MOUNTING BRACKET (w/ License Plate Bracket)

|

(a) Remove the 2 screws and front bumper extension mounting bracket. |

|

7. REMOVE FRONT BUMPER SIDE MOULDING LH

|

(a) Remove the 2 outside moulding retainers. |

|

(b) Detach the claw to remove the front bumper side moulding LH.

8. REMOVE FRONT BUMPER SIDE MOULDING RH

HINT:

Use the same procedure as for the LH side.

9. REMOVE FRONT BUMPER LOWER SIDE SUPPORT LH

|

(a) Remove the 2 clips. |

|

(b) Detach the 5 claws to remove the front bumper lower side support LH.

10. REMOVE FRONT BUMPER LOWER SIDE SUPPORT RH

HINT:

Use the same procedure as for the LH side.

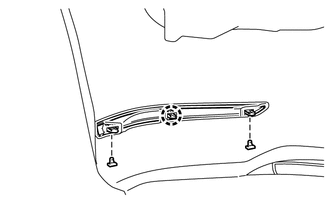

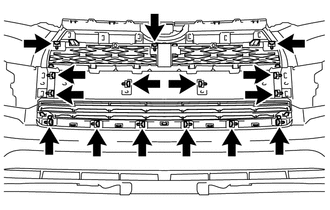

11. REMOVE NO. 2 RADIATOR GRILLE MOULDING

|

(a) Remove the 2 outside moulding retainers and 4 screws. |

|

|

(b) Detach the 4 claws to remove the No. 2 radiator grille moulding. |

|

12. REMOVE FRONT BUMPER SIDE MOULDING SUB-ASSEMBLY LH

|

(a) Remove the 3 outside moulding retainers. |

|

(b) Remove the 2 screws.

(c) Detach the 2 claws and guide to remove the front bumper side moulding sub-assembly LH.

13. REMOVE FRONT BUMPER SIDE MOULDING SUB-ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

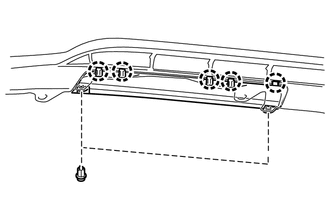

14. REMOVE FRONT BUMPER MOULDING SUB-ASSEMBLY

|

(a) Remove the 4 screws. |

|

|

(b) Remove the 15 outside moulding retainers. |

|

|

(c) Detach the 12 guides and 4 claws to remove the front bumper moulding sub-assembly. |

|

15. REMOVE FOG LIGHT ASSEMBLY LH

.gif)

16. REMOVE FOG LIGHT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER RADIATOR SUPPORT SEAL

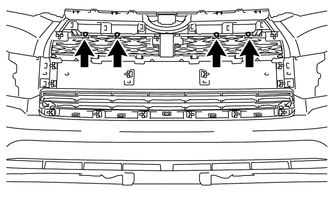

2. REMOVE FRONT BUMPER COVER

(a) Put protective tape around the front bumper cover.

(b) Remove the 3 bolts, 10 screws and 6 clips.

(c) ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FOG LIGHT ASSEMBLY LH

2. INSTALL FOG LIGHT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

3. INSTALL FRONT BUMPER MOULDING SUB-ASSEMBLY

(a) Atta ...

Other materials about Toyota 4Runner:

Installation

INSTALLATION

PROCEDURE

1. INSTALL WINDSHIELD WASHER MOTOR AND PUMP ASSEMBLY

(a) Install the windshield washer motor and pump assembly to the packing of the

washer jar.

2. INSTALL WASHER JAR

(a) Attach the guide to install the washer jar, and ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REFRESHING SEAT SWITCH

(a) Attach the 4 claws to install the refreshing seat switch.

2. INSTALL LOWER CENTER INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY

3. INSTALL NO. 2 CONSOLE BOX RETAINER

4. INSTALL UPPER CONSO ...

0.0267